Pressure Gauges

Series: GPG

Genese extensive range of Industrial grade Pressure Gauges (Bourdon Sensing / Diaphragm Sensing) are suitable to cater almost all process pressure / vacuum measurement needs accurately, safely and reliably. These gauges are designed and engineered to satisfy process requirements of industries like Oils/Gas Exploration, Refineries, Petrochemicals, Chemicals, Pharmaceutical, Power generation (Nuclear/Atomic/Thermal/Hydro), Metallurgy/Steel, Cement, Shipbuilding, Pulp/Paper, Synthetic Fiber, Food/Beverage, Hydraulics, Water Treatment, Storage/Tank farms, Fertilizer, Mining, On/offshore, HVAC, Fire protection, Defense manufacturing, Aerospace, OEMs etc…

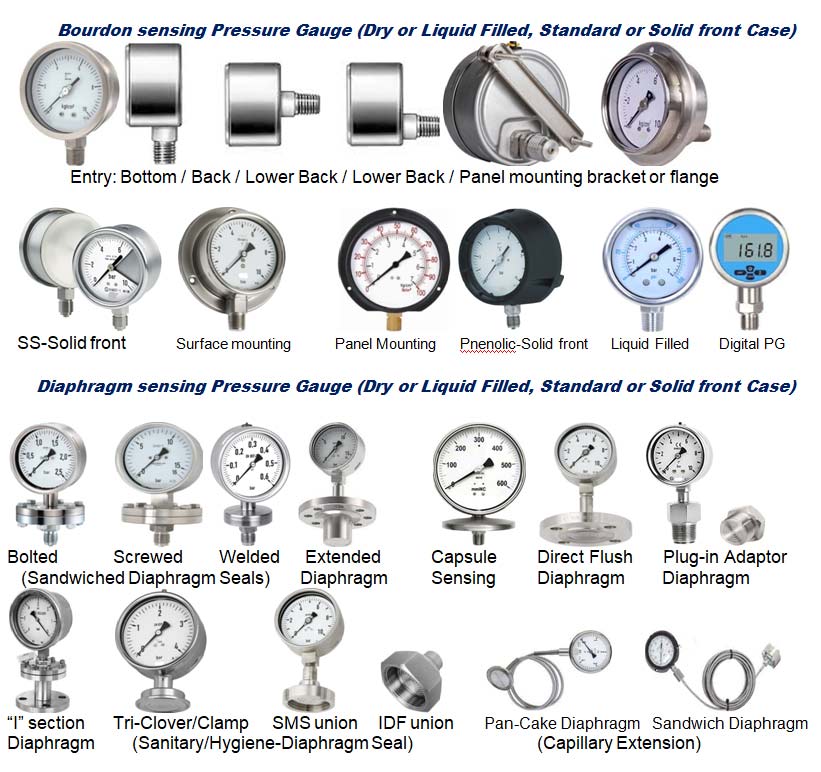

Bourdon Sensing Gauges are designed to meet process pressure / vacuum measurement needs accurately, safely, reliably and durably. It protect against extreme process environments which face system vibration, pulsation, pressure spikes and corrosion etc.. These are available in 1.5”/2”/2.5”/4”/4.5”/6”/10” dials, SS/Phenolic/Steel/ Aluminium cases, SS/Monel/Brass/Phosphorus Bronze working parts, With or without liquid filled SS/Phenolic cases, -1 to 1600Kg/Cm² range with 0.6/1Kg/Cm² minimum span, ±0.25% master gauge / ±1% standard & ±0.5% optional for standard gauge / ±2% (small gauge) accuracies, kg/cm2(g)/ bar(g)/ psi(g)/ kPa(g)/ MPa(g)/ mbar(g)/ mm WC(g)/ cm WC(g)/ m WC(g)/inch WC(g)/ mm Hg(g)/ cm Hg(g)/ inch Hg(g) measuring units, Threaded (M)/Flanged connections, Bottom/back entry with local/surface/flush panel/2” pipe mounting. Following are the bourdon sensing variants available in Dry Case, Liquid filled Case, and Solid Front/Safety Design Case.

Standard Bourdon Sensing Pressure Gauges are designed to satisfy the requirements of aggressive industrial process pressure/vacuum measurements. These are available in 4”/6”/10” dials, SS/Phenolic/Aluminium cases, SS/Monel working parts, with or without liquid filled SS case, -1 to 1600Kg/Cm² range with 0.6Kg/Cm² minimum span, ±1% accuracy and provided with different types of threaded connections, entry and mounting.

Small Size Bourdon Sensing Pressure Gauges are designed to satisfy the requirements of utility, general purpose, industrial, OEM and commercial process pressure/vacuum measurement typically found in HVAC, refrigeration, fire protection, food/beverage, lubricating circuits and hydraulics applications. These are available in 1.5”/2”/2.5” dials, SS/Steel cases, SS/Brass/Phosphorus Bronze working parts, with or without liquid filled 2”/2.5” SS cases, -1 to 400Kg/Cm² range (SS internals) / -1 to 250Kg/Cm² (Brass/Bronze internals), ±2% accuracy and provided with different types of threaded connections, entry and mounting.

Solid Front Bourdon Sensing Pressure Gauges are provided with blow out safety disc at back and an extra safety wall within case which creates a chamber to accommodate pressure sensing element. Blow out disc allows releasing the pressure from the back immediately and safety wall prevent the pressure release from the front when accidental rupture of sensing element which leads to satisfy workplace safety. High pressure spikes, fatigue, heavy vibrations and pulsations are key causes of bourdon tube ruptures where dangerous chemicals, gases and hot steams are processed under pressure. Solid front gauges are available in 4”/4.5”/6”/10” dials, SS/Phenolic cases, SS/Monel working parts and with or without liquid filled case.

Liquid Filled Bourdon Sensing Pressure Gauges are designed to meet all applications that involve high dynamic shocks/vibrations, mechanical shocks and pressure pulsations. Liquid filling eliminates corrosion, moisture penetration and icing due to the ambient atmosphere and it also lubricates moving components and dramatically reduce wear and tear of the movement. It also dampens the vibrations that occur and thus takes the load of the mechanical components of the pressure gauge which enables easier pressure readings. Liquid filled standard / small gauges are available in 2”/2.5”/4”/4.5”/6”/10” dials, SS/Phenol cases, SS/Monel/Brass/Phosphorus Bronze working parts.

Receiver Gauge Bourdon sensing designed suitably to receive pneumatic signals from flow and level Transmitters. These are available in 4”/6” dials, SS case, SS working parts, 0.2 to 1Kg/Cm² / 3 to 15PSI range, ±1% accuracy and provided with different types of threaded connections, entry and mounting.

Quality assurance programs strictly conform to relevant national/international standards and Pressure Gauges are inspected, tested and calibrated at the factory before shipment.

Products List

| Pressure Gauges (Bourdon Sensing) |

| Pressure Gauge-Bourdon Sensing (Dry Case) |

| Pressure Gauge-Bourdon Sensing (Liquid filled Case) |

| Pressure Gauge-Bourdon Sensing-Solid Front (Dry Case) |

| Pressure Gauge-Bourdon Sensing-Solid Front (Liquid filled Case) |

| Pressure Gauge-Bourdon Sensing (Dry Case)-Small Size |

| Pressure Gauge-Bourdon Sensing (Liquid filled Case)-Small Size |

| Receiver Gauge-Bourdon Sensing (Dry Case) |

| Absolute Pressure Gauge-Bourdon Sensing (Dry Case) |

| Master Pressure Gauge-Bourdon Sensing (Dry Case) |

| Pressure Gauges (Diaphragm Sensing) |

| Pressure Gauge-Diaphragm Sensing (Dry Case) |

| Pressure Gauge-Diaphragm Sensing (Liquid filled Case) |

| Pressure Gauge-Diaphragm Sensing-Solid Front (Dry Case) |

| Pressure Gauge-Diaphragm Sensing-Solid Front (Liquid filled Case) |

| Capsule Pressure Gauge-Diaphragm Sensing (Dry Case)-Compact |

| Capsule Pressure Gauge-Diaphragm Sensing-Solid Front (Dry Case)-Compact |

| Capsule Pressure Gauge-Diaphragm Sensing (Dry Case)-Heavy Duty |

| Capsule Pressure Gauge-Diaphragm Sensing-Solid Front (Dry Case)-Heavy Duty |

| Hygiene Pressure Gauge-Diaphragm Sensing (Dry Case) |

| Hygiene Pressure Gauge-Diaphragm Sensing (Liquid filled Case) |

| Absolute Pressure Gauge-Diaphragm Sensing (Dry Case) |

| Absolute Pressure Gauge-Diaphragm Sensing (Liquid filled Case) |

| Absolute Pressure Gauge-Bellow Sensing (Dry Case) |

| Mud Pressure Gauge-Diaphragm Sensing (Liquid filled case) |

| Accessories |